Waste Not, Save a Lot

Asphalt is the “most recycled and reused material” in America. Recycling asphalt involves the milling of existing asphalt pavement that is then mixed with an emulsion binder and other additives as needed, and then placed back and compacted to create a new recycled road.

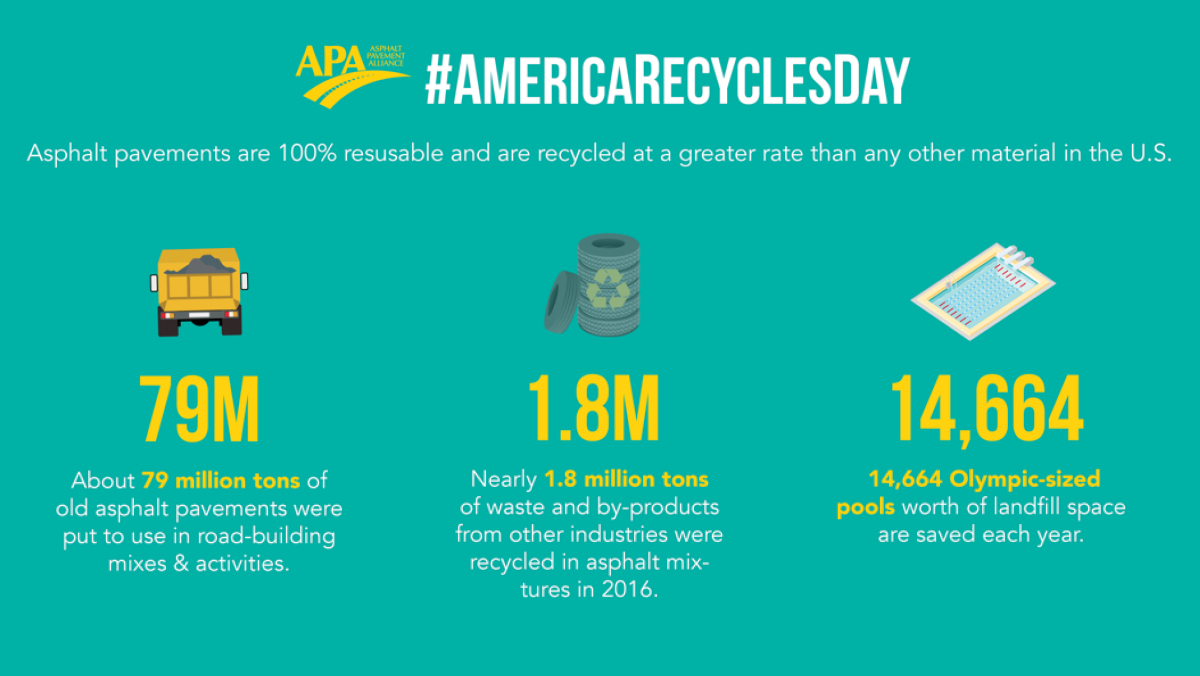

Infographic provided by the asphalt Pavement Alliance.

Infographic provided by the asphalt Pavement Alliance.

Why Use Recycled Asphalt?

First, there’s the cost. Recycled asphalt treatments are less costly than paving or repaving with new asphalt. Typical savings of over 30 to 40 % are realized when using recycled materials. The bulk of what you need is already in the milled material. There’s also the environmental impact, as recycled asphalt treatments have a smaller carbon footprint because aggregates are reused, binder consumption is reduced, and these treatments require less trucking and less energy during construction. All of these factors lead to a reduction in emissions.

There are several different recycling methods and Ergon Asphalt & Emulsions can help you determine which process best suits your specific needs.

Recycling Methods

- In the Hot In-Place Recycling (HIR) process, up to two inches of existing pavement is heated and milled, mixed with an asphalt emulsion binder and other additives as necessary, and then replaced and compacted.

-

Cold In-Place Recycling (CIR) is a process in which the existing distressed pavement is recycled without the use of heat. This pavement is milled at a typical depth of three to five inches. After milling, the material undergoes crushing in order to reach an optimum particle size and is then mixed with an asphalt emulsion binder and other additives as necessary, replaced and compacted.

Cold In-Place Recycling Application

Cold In-Place Recycling Application - Cold Central Plant Recycling (CCPR) is similar to CIR except once the existing asphalt has been milled on-site, it is taken to a central plant where it is crushed or sized, mixed with an emulsion binder and brought back to a location to be paved.

- A Full Depth Reclamation (FDR) treatment is applied when you need to build more structural strength into your existing pavement section. Typical depths of 6-12 inches of existing pavement is pulverized, blended with base materials, graded or shaped and then mixed with an emulsion to provide a more stable road base. The material is then compacted.

Please note recycled asphalt treatments require a surface wearing course. That course is determined by the structural requirements for the roadway. For example, a roadway with a low traffic volume might only need a double chip seal while an urban highway might need four inches of HMA to be placed over the surface for even greater strength.

More Questions?

As your roadway resource, we keep your budget and project in mind, with products on hand to meet your roadway needs. Contact one of our team members for more information on your cost effective options for recycled asphalt binders.