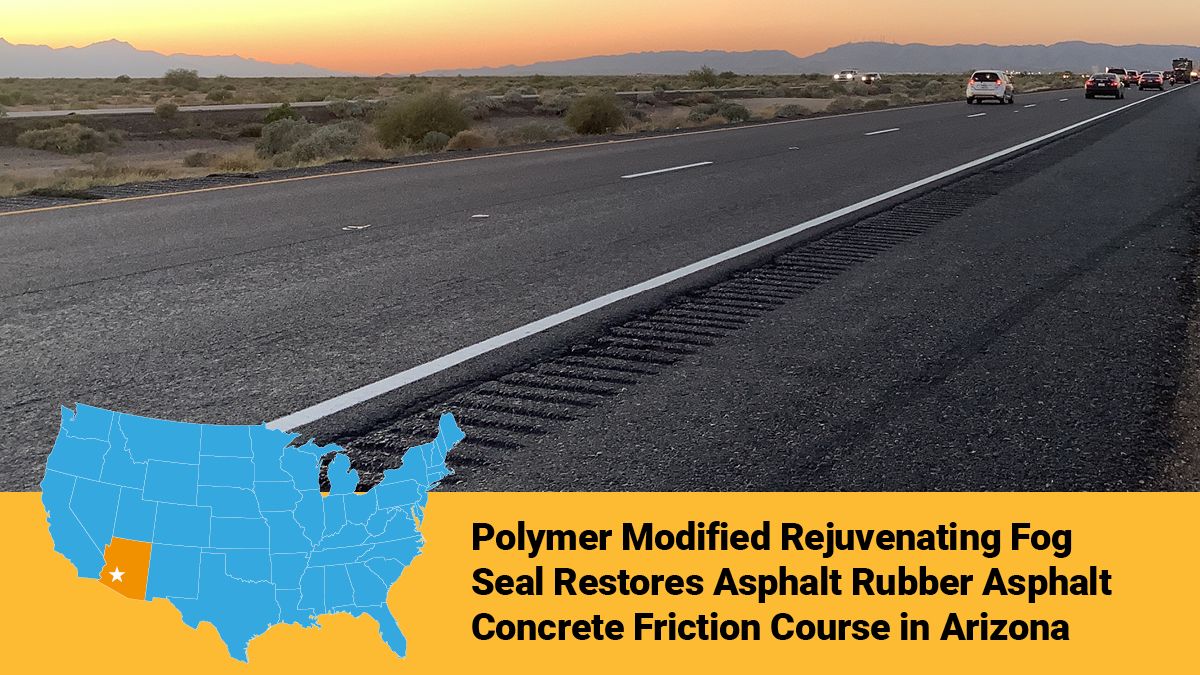

Ergon Asphalt & Emulsions (Ergon A&E) had the opportunity to supply PMRE on an ARACFC surface along I-10 between Cactus Boulevard and Riggs Road that was due for maintenance.

Benefits of ARACFC Surfaces

With ARACFC surfaces, asphalt binder is mixed with ground recycled tire rubber and other additives. These surfaces are considered a type of open-graded friction course (OGFC) because they provide increased friction by allowing water to drain to the sides of the roadway during rain events instead of collecting on the surface. This function helps to prevent hydroplaning, increase traction and positively impact driver safety. ARACFC surfaces provide durable roadways by utilizing a heavy film thickness. Minimal road noise is an additional benefit. They are ideal for high-traffic, high-speed roads like I-10.

Why PMRE Fog Seal?

A fog seal using PMRE can extend the life of ARACFC/OGFC surfaces, as it inhibits raveling and contains a rejuvenating agent that restores essential properties to aging surfaces. Its polymer modification allows for a more flexible binder that helps prevent further raveling throughout the life of the treatment. The goal for the PMRE application on I-10 was to delay a more costly replacement project.

Application Highlights

On November 12-13, 2022, the Contractor, Cactus Asphalt, applied PMRE at an average of 0.13 gallons per square yard to approximately eight miles of I-10 across multiple lanes, including entrance and exit ramps leading to the AZ-202 loop. Ergon A&E’s Chandler, Arizona, plant supplied the emulsion for the project, which called for a total of 375 tons of PMRE.

ADOT remains pleased with the outcome of the PMRE application, which has proven to extend the service life of their ARACFC surfaces. Utilizing PMRE allows ADOT to make the most effective use of their limited budget over time, and they plan to continue utilizing PMRE fog seal as part of their maintenance strategy.

In addition to PMRE, Ergon offers a variety of conventional and specialty fog seal options to meet your specific roadway needs. Contact your local salesperson to learn more about our fog seal solutions for you.