Oklahoma DOT Evaluates New Pavement Preservation Treatment

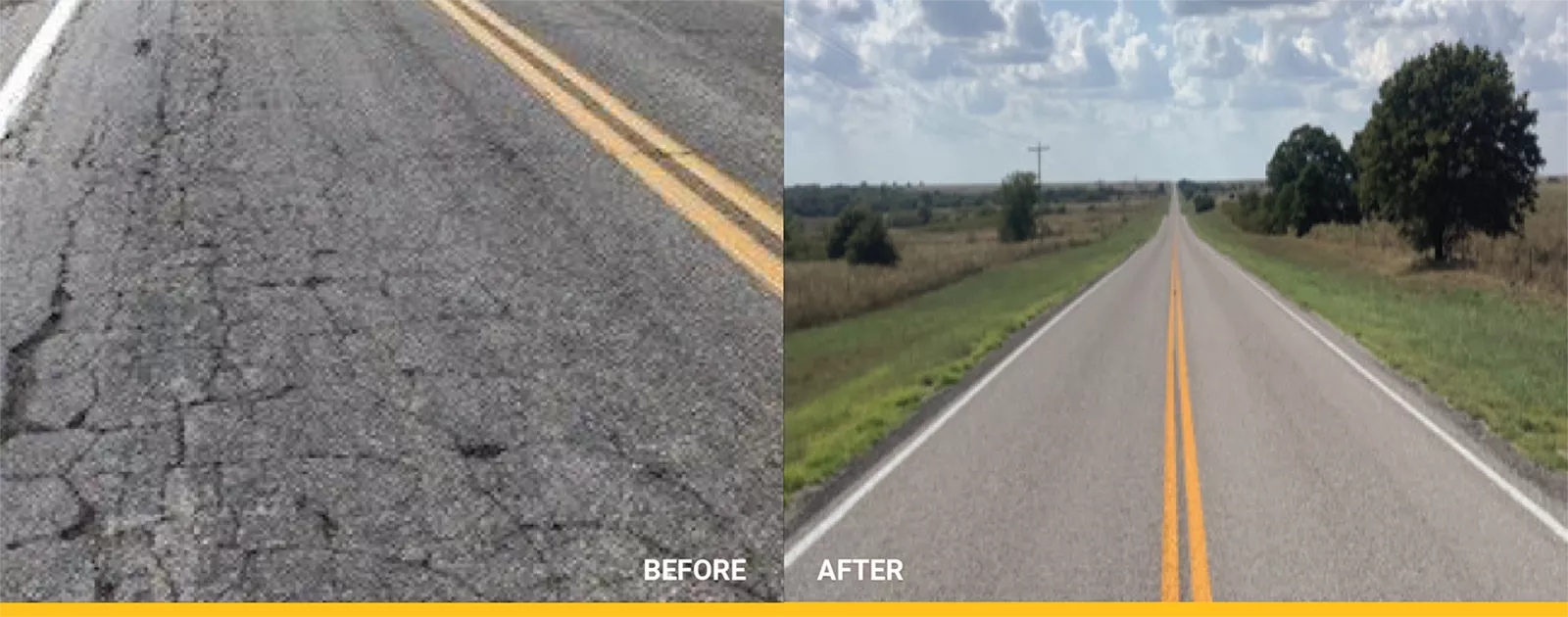

While the Oklahoma Department of Transportation (ODOT) had experience with pavement preservation, they were interested in additional treatment options for roads in their network. Hwy 32, which was experiencing longitudinal and transverse cracking, provided an opportunity for ODOT to consider a new treatment to add to their preservation toolbox that was less costly and less time consuming than the previous method used to address these common distresses .

Right Treatment, Right Road, Right Time

Pavement preservation using asphalt emulsions has proven to keep roads in good condition longer and provide significant savings over the alternative “fix the worst first” and/or hot mix only approaches to road maintenance. As reported in the Federal Lands Transportation Fact Sheet on Pavement Preservation: “An FHWA pavement preservation study found that a dollar spent on pavement preservation can halve the cost of maintaining a road through its life cycle.”

ODOT’s Traditional Approach – Blade-Laid Hot Mix + Chip Seal

To address cracking on Hwy 32 in times past, ODOT would apply a blade-laid hot mix, placing asphalt mix at various depths (typically no greater than one inch) to level the profile of the roadway. This was followed by a chip seal that served as a wearing course and helped prevent moisture intrusion.

This was the only method ODOT was aware of at the time that would yield the results they desired at the low price point allotted for low volume roadways like Hwy 32. While an effective method for meeting immediate road needs, the blade-laid hot mix + chip seal would not create the result ODOT desired, which was to keep roads in good condition for a longer period of time.

Introducing the Scrub Seal Treatment — A Lasting Mass Crack Sealant

At Ergon A&E, we strive to not only provide quality products, but also to guide agencies in the direction of best practices for their network needs while offering technical support along the way. Ergon A&E’s western Oklahoma Area Sales Manager Johnny Roe and Technical Marketing Manager BJ Cottman had been in talks with Tracy Terrill, ODOT District 7 Maintenance Engineer, about a solution that would not only address mass cracking, but provide a longer-lasting seal and improve durability at a lower price than the blade-laid + chip seal process. That solution was a scrub seal.

How Scrub Seal is Applied

During the scrub seal process, emulsion is sprayed at a specified rate onto the road surface. The emulsion is then immediately forced deep into voids and cracks using a mechanized broom sled attached to the distributor truck. This method ensures emulsion reaches cracks at a greater depth than traditional chip seals to yield a longer-lasting seal. Aggregate is then applied onto the emulsion, and the new surface is rolled, swept and can be returned to traffic typically within 1-1.5 hours of the application.

Scrub Seal on Highway 32

Upon surveying distresses and evaluating the benefits of scrub seal, ODOT decided to apply the treatment along 17 centerline miles of Hwy 32 that were experiencing mass cracking. Following the application, ODOT planned to monitor the new surface to determine if scrub seal was a suitable solution to add to their preservation toolbox.

Ergon A&E’s eScrub was the selected emulsion for the scrub seal application.

eScrub Rejuvenating Scrub Seal

eScrub is a polymer modified rejuvenating emulsion used to repair pavements exhibiting mass cracking, friction loss, oxidation and raveling, enhancing the quality and durability of asphalt pavements long term.

Rejuvenating Scrub Seal Performance and Cost Benefits

When applying a scrub seal using eScrub, agencies see typical life cycle extensions of five to seven years. And using a project-specific cost of $2.05 per sq yd, this treatment is less expensive than the average cost of blade-laid hot mix + chip seal at $3.73 per sq yd.

Application Highlights

The scrub seal project began on June 22, 2021, and was completed in five days. eScrub was applied at 0.38 gallons per sq yd, and 3/8” chips were used for the surface aggregate.

The ODOT District 7 Maintenance Division utilized a pilot car throughout the project so traffic could continue to flow during construction. Traffic was returned following final rolling over newly scrub sealed sections. The day following application, ODOT Maintenance forces used a rotary broom to remove excess chips.

Scrub Seal Cost Savings

Moving forward, by using the scrub seal technique, ODOT will see a cost savings of 45% in lieu of their typical treatment.

Bryce Lawson, P.E., ODOT District 7 Assistant Maintenance Engineer, said: “To date, the project is performing as expected, and we are looking forward to monitoring the long-term success of the scrub seal. We are grateful for our partnership with Ergon, as they explained the scrub seal process and worked alongside our maintenance crews throughout the duration of the project. We learned a new tool to put in our toolbox as we continue in our search for ways to better maintain Oklahoma’s highway system.”

Long-Term Strategy

Realizing the success of the Hwy 32 scrub seal, the ODOT District 7 Maintenance Division plans to continue to use the scrub seal technique on other roads in their network.

Contact one of our expert team members to learn how you can seal mass cracking and improve durability with eScrub rejuvenating scrub seal today.