What is Tack Coat?

Multiple asphalt layers create a single uniform pavement structure that flexes under stress. The bond that connects these layers is a thin liquid asphalt emulsion called tack coat. Ergon’s eTac is an innovative trackless bond/tack coat emulsion that provides exceptional adhesion between pavement sections, reduces slippage and allows for a significant reduction in delamination. Unlike the compromised bond of many traditional tack coats, which can cause pavement to slide under traffic loads resulting in slippage cracks and failure, eTac is designed to hold tight to asphalt and the bond created melds asphalt layers into one cohesive pavement unit. These attributes made eTac the ideal solution to test along U.S. Route 160.

U.S. Route 160 Project Details

Over two days in mid-October 2021, eTac was placed on a hot mix pavement project mat along U.S. Route 160 west of Kayenta, Arizona. Ergon Asphalt & Emulsions supplied the eTac and on Thursday, October 14, Fann Contracting began applying the trackless tack at shot rates of 0.08, 0.10 and 0.12 gallons per square yard. Friday’s demonstration included additional sections that received eTac at 0.10 and 0.12 gallons per square yard. “At the start of demonstrations, the morning ambient and pavement surface temperatures for both days registered below 40°F. By early afternoon, temperatures were in the upper 40s,” said Nye McCarty, P.E., ADOT’s Flagstaff Regional Materials Engineer. “The emulsion had been kept in a distributor truck since the week prior due to weather delays but remained very stable. It was in a non-tacky state within 10 minutes and was fully broken within 15 minutes. No tracking of any kind was observed after the material had completely broke.” Compared to conventional tack coats, the benefits of eTac were immediately realized as the liquid emulsion held tight to the asphalt and did not pull up onto tires and equipment. Once the asphalt was fully cooled, it was on to the lab for bond strength testing.

Shear Bond Strength Testing of eTac

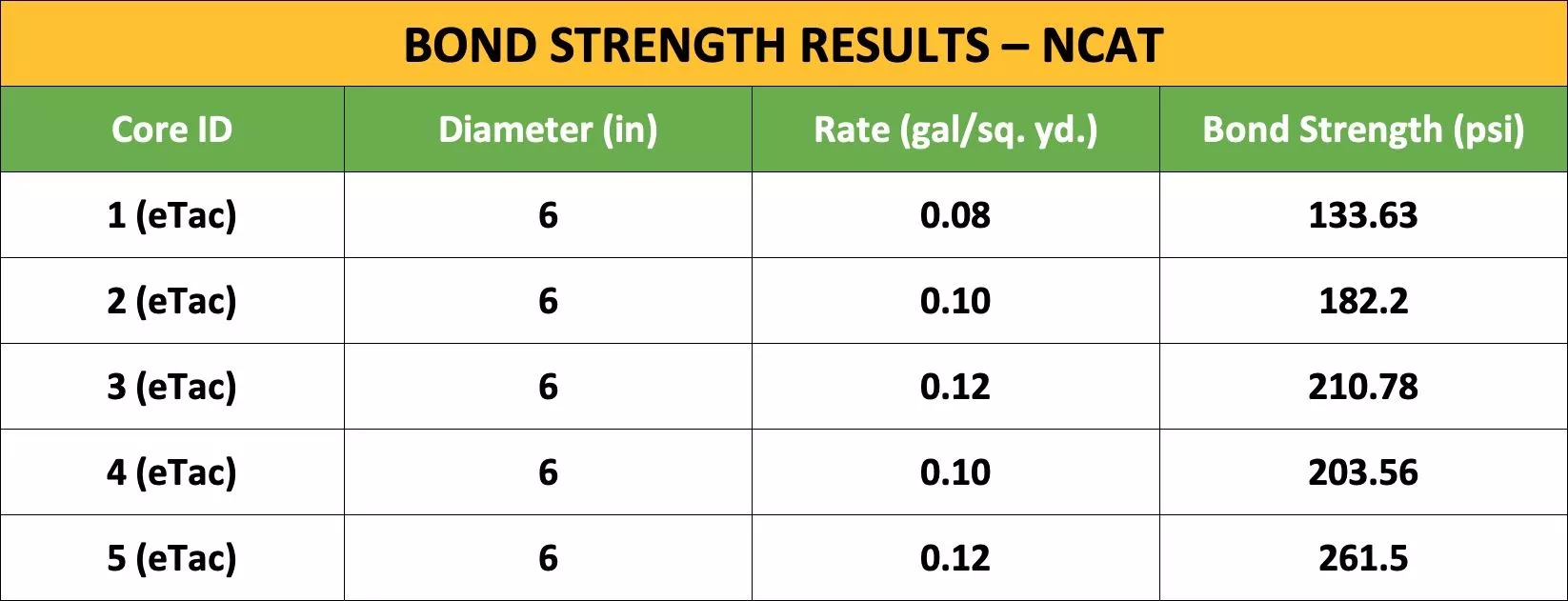

ADOT took 6-inch diameter full-depth cores for each application rate placed both Thursday and Friday and sent samples to the National Center for Asphalt Technology (NCAT) laboratory for shear bond strength testing. Previous attempts to obtain full-depth cores from where conventional CSS-1H was placed proved challenging according to ADOT, as the new asphalt delaminated from the old asphalt while coring. Bonding strength over 100 psi is considered passing by some state agencies. Results below illustrate eTac’s remarkable bond strength (psi) numbers.

__________________

Status of shear testing for U.S. Route 160’s tack cores as of October 2021. Data provided by NCAT.

eTac Core Samples Register Remarkable NCAT Bond Strength Test Data

ADOT project personnel were extremely pleased with the performance of eTac on U.S. Route 160. eTac’s ability to properly bond to asphalt not only provided ADOT with full-depth core samples to test, but the trackless tack coat's firm grip to asphalt also reduced cleanup time and crew exposure to traffic — all important elements in achieving safe roads built to last. Contact your local Ergon representative for more information on how your roads can benefit from eTac.